Building an efficient gas impingement system is crucial for the performance and reliability of your firearm. Whether you're a gun enthusiast or a professional, understanding the intricacies of this system can greatly enhance your shooting experience. In this blog post, we'll explore five essential tips to design the ultimate gas impingement system, ensuring optimal functionality and precision.

1. Choose the Right Barrel Profile

The barrel profile plays a significant role in the performance of your gas impingement system. It determines the gas flow and pressure, which directly affects the cycling of the firearm. Here are some key considerations when selecting a barrel profile:

- Contour: Choose a barrel contour that suits your shooting style and intended use. A heavier contour may be preferable for long-range shooting, as it provides better accuracy and heat dissipation. On the other hand, a lighter contour is ideal for faster handling and reduced weight.

- Twist Rate: The twist rate of the barrel affects the stability and accuracy of the bullet. A faster twist rate is suitable for shooting heavier bullets, while a slower twist rate is optimal for lighter projectiles. Ensure the twist rate matches the intended ammunition to prevent stability issues.

- Length: Barrel length is crucial for gas impingement systems. Longer barrels provide more time for gas to expand and cycle the action, resulting in a smoother operation. However, shorter barrels are more portable and offer faster handling. Consider your specific needs and shooting environment when choosing the barrel length.

2. Optimize Gas Port Size and Location

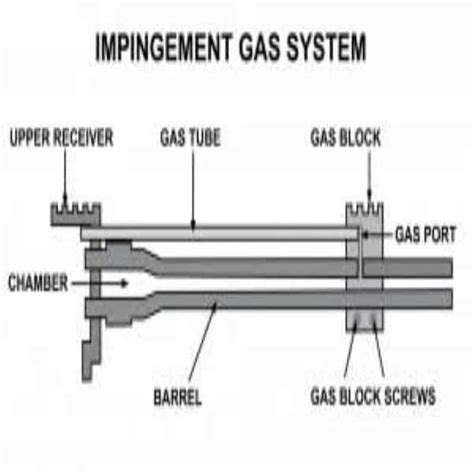

The gas port is a critical component of the gas impingement system, as it controls the amount of gas that enters the system to cycle the action. Here's how to optimize its size and location:

- Size: The size of the gas port directly affects the amount of gas used to cycle the action. A larger port allows more gas to enter, which can be beneficial for heavier ammunition. However, a smaller port provides better control and precision for lighter rounds. Choose the appropriate size based on your ammunition choice.

- Location: The location of the gas port is equally important. It should be positioned to ensure efficient gas flow and proper cycling. Consider the barrel profile and the intended use of the firearm when determining the ideal gas port location. Consult with experienced gunsmiths or refer to manufacturer recommendations for precise placement.

3. Select High-Quality Components

The gas impingement system relies on various components to function optimally. Investing in high-quality parts can significantly enhance the performance and longevity of your firearm. Here are some components to prioritize:

- Gas Block: A well-made gas block ensures proper gas flow and prevents gas leaks. Look for gas blocks with precise machining and durable materials. Consider adjustable gas blocks for fine-tuning the gas system to different ammunition types.

- Gas Tube: The gas tube connects the gas block to the bolt carrier group. Opt for a gas tube made from high-grade steel or stainless steel for durability and corrosion resistance. Ensure it fits snugly to prevent gas leaks and maintain consistent performance.

- Bolt Carrier Group: The bolt carrier group is responsible for cycling the action. Choose a bolt carrier group made from high-quality materials, such as chrome-moly steel or stainless steel. Look for components with precise machining and a smooth finish to ensure reliable functioning.

4. Fine-Tune the Buffer System

The buffer system plays a crucial role in managing the recoil and cycling of the firearm. By fine-tuning the buffer system, you can optimize the performance of your gas impingement setup. Here's how to achieve that:

- Buffer Weight: The weight of the buffer directly affects the cycling speed and felt recoil. Heavier buffers provide a smoother cycling action, while lighter buffers offer faster cycling and reduced recoil. Choose the buffer weight based on your preferred shooting style and intended use.

- Buffer Spring: The buffer spring controls the buffer's movement and impacts the cycling rate. A stiffer spring provides a more controlled cycling action, while a softer spring allows for faster cycling. Consider your ammunition choice and desired cycling speed when selecting the buffer spring.

- Buffer Tube: The buffer tube houses the buffer and spring. Ensure it is securely attached and free from any play or wobble. A well-fitted buffer tube maintains the stability of the buffer system, leading to consistent performance.

5. Consider Customization and Tuning

Once you have the basic components in place, consider customizing and tuning your gas impingement system to achieve the best performance. Here are some options to explore:

- Gas Block Adjustment: Some gas blocks offer adjustable features, allowing you to fine-tune the gas flow based on different ammunition types. This customization ensures optimal cycling for various rounds, resulting in improved accuracy and reliability.

- Buffer Spring Tuning: If your firearm exhibits excessive recoil or cycling issues, consider tuning the buffer spring. By adjusting the spring tension, you can control the cycling rate and reduce felt recoil. This customization ensures a more comfortable shooting experience and better control over the firearm.

- Porting and Muzzle Devices: Porting and muzzle devices can be added to further optimize the gas impingement system. Porting reduces recoil and muzzle rise, improving accuracy and control. Muzzle devices, such as compensators or flash hiders, can enhance recoil management and conceal muzzle flash.

By following these five tips, you can design an efficient and reliable gas impingement system tailored to your specific needs. Remember, a well-built gas impingement setup not only enhances the performance of your firearm but also contributes to a more enjoyable shooting experience. So, take the time to choose the right components, optimize the system, and fine-tune it to perfection.

Conclusion

Designing the ultimate gas impingement system requires careful consideration of various factors, from the barrel profile to the buffer system. By selecting the right components, optimizing gas flow, and fine-tuning the setup, you can achieve exceptional performance and reliability. Remember to consult with experts, experiment with different customizations, and always prioritize safety when working on your firearm. With these tips in mind, you're well on your way to creating a gas impingement system that delivers precision and accuracy shot after shot.

What is a gas impingement system, and how does it work?

+

A gas impingement system is a mechanism used in firearms to harness the energy from propellant gases to cycle the action. When a round is fired, some of the gas is directed through a port in the barrel, which pushes against a piston or bolt carrier, forcing it to move backward and eject the spent casing. This action then chambers a new round, ready for the next shot.

Can I use any barrel profile with a gas impingement system?

+

While most barrel profiles can be used with a gas impingement system, certain profiles are better suited for specific purposes. Heavier profiles are ideal for long-range shooting, offering better accuracy and heat dissipation. Lighter profiles are preferred for faster handling and reduced weight. Choose a profile that aligns with your intended use and shooting style.

How do I know if my gas port size and location are optimal?

+

The optimal gas port size and location depend on various factors, including the ammunition you use and the intended application of your firearm. Consult with experienced gunsmiths or refer to manufacturer recommendations for precise guidance. They can help you determine the ideal gas port configuration for your specific setup.

Why is it important to use high-quality components in a gas impingement system?

+

High-quality components ensure the reliability and longevity of your gas impingement system. They are designed to withstand the high pressures and temperatures generated during firing, reducing the risk of malfunctions and increasing the overall lifespan of your firearm. Investing in quality parts provides peace of mind and optimal performance.

Can I customize my gas impingement system further beyond the tips provided?

+

Absolutely! Customization is a significant part of the gas impingement system’s appeal. Beyond the tips mentioned, you can explore options like adjustable gas blocks, muzzle brakes, and different buffer spring weights to fine-tune the system’s performance to your specific needs and preferences. Experimentation and customization can lead to a truly unique and optimized setup.