7 Tips to Design the Ultimate Tracer Ammo: A Comprehensive Guide

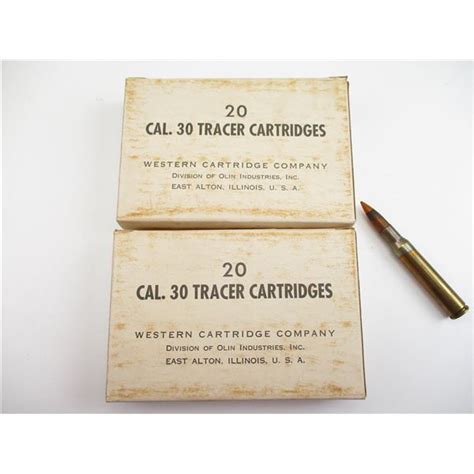

Creating your own tracer ammunition can be an exciting and rewarding endeavor for firearms enthusiasts and hobbyists. Tracer rounds, with their mesmerizing trails of light, offer a unique and captivating shooting experience. However, designing effective tracer ammo requires careful consideration of various factors. In this guide, we'll explore seven essential tips to help you craft the ultimate tracer rounds.

1. Choose the Right Tracer Material

The choice of tracer material is crucial for the performance and safety of your ammunition. Common options include:

- Incandescent Tracers: These tracers produce a bright, visible light by burning a solid fuel. They are cost-effective and provide excellent visibility, but may have a shorter range.

- Phosphorus-Based Tracers: Phosphorus tracers offer a longer range and brighter light, making them ideal for low-light conditions. However, they can be more expensive and require careful handling due to their chemical properties.

- Glow-in-the-Dark Tracers: Utilizing phosphorescent materials, these tracers charge in daylight and emit a faint glow in low light, providing a subtle yet effective visual aid.

🌟 Note: Always prioritize safety when working with tracer materials. Follow recommended handling and storage guidelines to prevent accidents.

2. Optimize Bullet Design

The design of the bullet itself plays a significant role in the performance of tracer ammunition. Consider the following aspects:

- Bullet Weight: Heavier bullets may have better stability and accuracy, but can affect the visibility of the tracer.

- Bullet Shape: Pointed or boat-tail designs can improve accuracy and range, while flat-based bullets may offer better tracer visibility.

- Bullet Material: Choose a material that balances accuracy and tracer performance. For example, lead is common for its cost-effectiveness, but copper-jacketed bullets may offer better accuracy.

3. Select the Ideal Primer

The primer ignites the propellant and is crucial for the overall performance of the ammunition. When selecting a primer, consider:

- Primer Sensitivity: Choose a primer with the right sensitivity for your application. Too sensitive primers may result in premature ignition, while less sensitive primers may not provide the desired performance.

- Primer Type: Large pistol primers are often used for tracer ammunition due to their consistent ignition and reliability.

4. Control the Powder Charge

The powder charge is responsible for propelling the bullet and igniting the tracer material. Here's what to consider:

- Powder Type: Select a powder that provides the desired velocity and pressure for your tracer rounds. Fast-burning powders are often used for their ability to generate high pressure quickly.

- Powder Quantity: The amount of powder used will impact the velocity and accuracy of your ammunition. Start with recommended loads and adjust based on your specific needs and the performance of your firearm.

5. Ensure Proper Seating and Crimping

Seating and crimping the bullet correctly is essential for consistent and safe ammunition. Follow these tips:

- Seating Depth: Ensure the bullet is seated to the correct depth to maintain proper gas seal and prevent setback.

- Crimping: Crimping the bullet into the case helps prevent setback and ensures a secure hold. Use the appropriate crimping method for your bullet type.

6. Test and Iterate

Testing your tracer ammunition is crucial to ensure its performance and safety. Here's a suggested process:

- Start with a small batch of ammunition, testing for functionality and safety.

- Evaluate the tracer's visibility, accuracy, and overall performance.

- Make adjustments to your design based on the test results.

- Repeat the testing process until you achieve the desired results.

7. Safety First

Creating tracer ammunition involves working with potentially hazardous materials and equipment. Always prioritize safety by:

- Wearing appropriate personal protective equipment, including eye and ear protection.

- Working in a well-ventilated area to minimize exposure to gases and fumes.

- Handling chemicals and materials with care, following recommended safety guidelines.

- Keeping a safe distance from the firearm when firing tracer ammunition.

By following these seven tips, you can design tracer ammunition that performs reliably and safely. Remember, creating tracer ammo is a complex process, and it's essential to approach it with caution and a thorough understanding of the principles involved.

Conclusion

Designing tracer ammunition is an exciting and rewarding challenge for firearms enthusiasts. By selecting the right materials, optimizing bullet design, and following safe practices, you can create tracer rounds that offer an exceptional shooting experience. Remember to test and refine your designs to ensure optimal performance and safety. With these tips in mind, you're well on your way to crafting the ultimate tracer ammo.

What safety precautions should I take when handling tracer materials?

+

When working with tracer materials, it’s crucial to prioritize safety. Always wear personal protective equipment, including gloves, eye protection, and a respirator. Work in a well-ventilated area and follow the handling and storage guidelines provided by the manufacturer. Additionally, keep a safe distance from the firearm when firing tracer ammunition to avoid any potential hazards.

Can I use any bullet for tracer ammunition?

+

While it’s possible to use a variety of bullets for tracer ammunition, the choice of bullet design can impact the performance and visibility of the tracer. Flat-based bullets may offer better tracer visibility, while pointed or boat-tail designs can improve accuracy and range. Consider the specific requirements of your application and choose a bullet that aligns with your goals.

What are the benefits of using phosphorus-based tracers?

+

Phosphorus-based tracers offer several advantages. They provide a longer range and brighter light, making them ideal for low-light conditions. This can be particularly useful for tactical or night-time shooting scenarios. However, they do require careful handling due to their chemical properties, so always follow safety guidelines when working with these tracers.