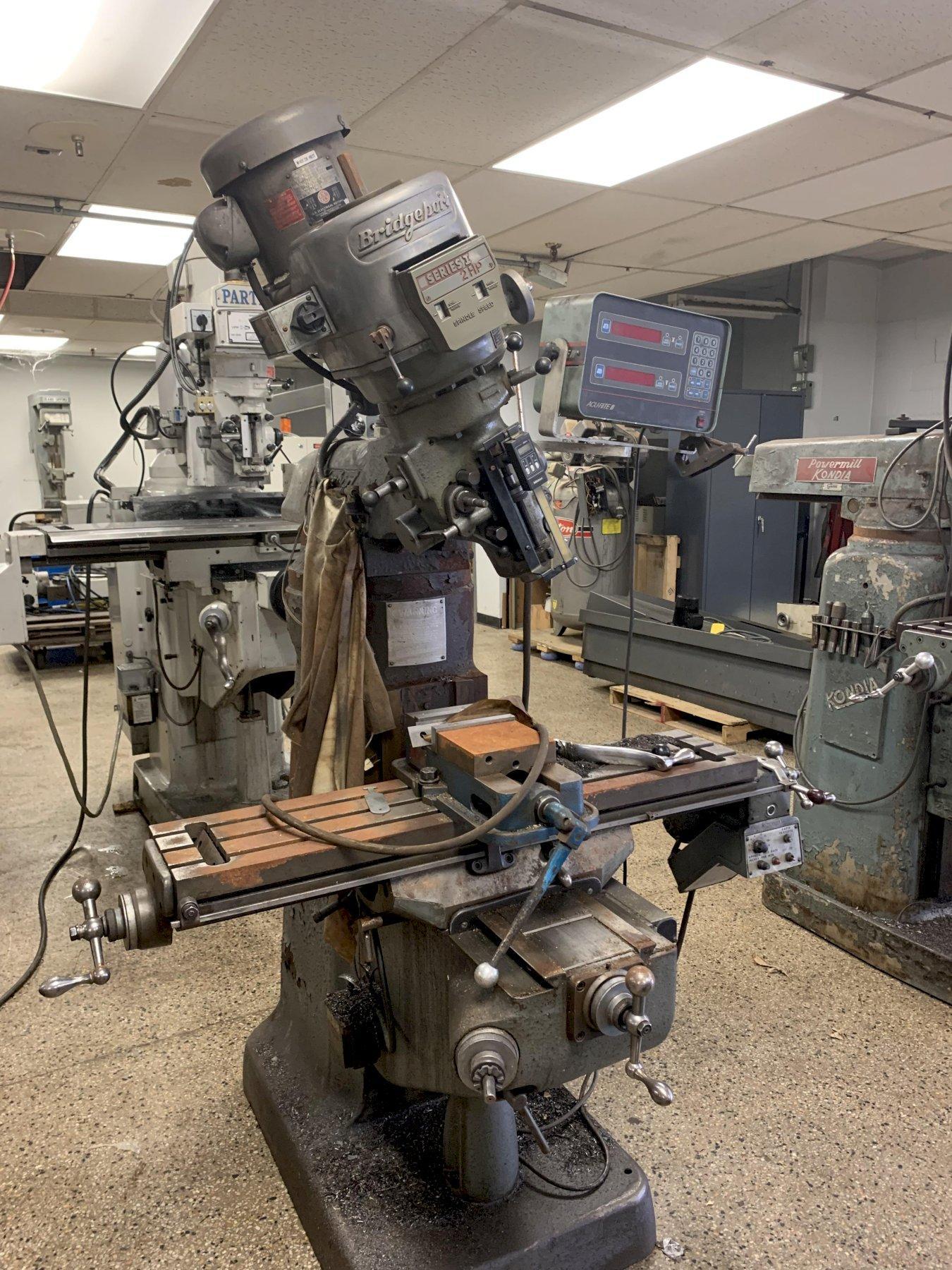

The Bridgeport milling machine is an iconic piece of machinery that has become synonymous with precision and versatility in the world of manufacturing and engineering. With its distinctive design and robust construction, it has earned its place as a staple in many workshops and factories. In this blog post, we will delve into the history, features, and applications of the Bridgeport milling machine, exploring why it remains a popular choice for professionals and enthusiasts alike.

A Legacy of Innovation

The Bridgeport milling machine has a rich history that spans several decades. It was first introduced in the 1930s by the Bridgeport Machines, Inc., a company founded by Rudy Krieg and Gustave Roux in Bridgeport, Connecticut. The machine was designed to meet the growing demand for precision milling in various industries, including aerospace, automotive, and manufacturing.

The original Bridgeport milling machine, known as the Series I Standard, featured a simple yet effective design. It had a sturdy cast iron construction, ensuring stability and accuracy during machining operations. Over the years, Bridgeport Machines, Inc. continuously improved and refined their design, introducing new models and enhancements to keep up with the evolving needs of the industry.

Key Features and Advantages

The Bridgeport milling machine offers a range of features that contribute to its popularity and versatility:

- Versatility: Bridgeport machines are known for their ability to handle a wide variety of materials and machining operations. From cutting metals to shaping plastics, these machines can accommodate a broad range of applications.

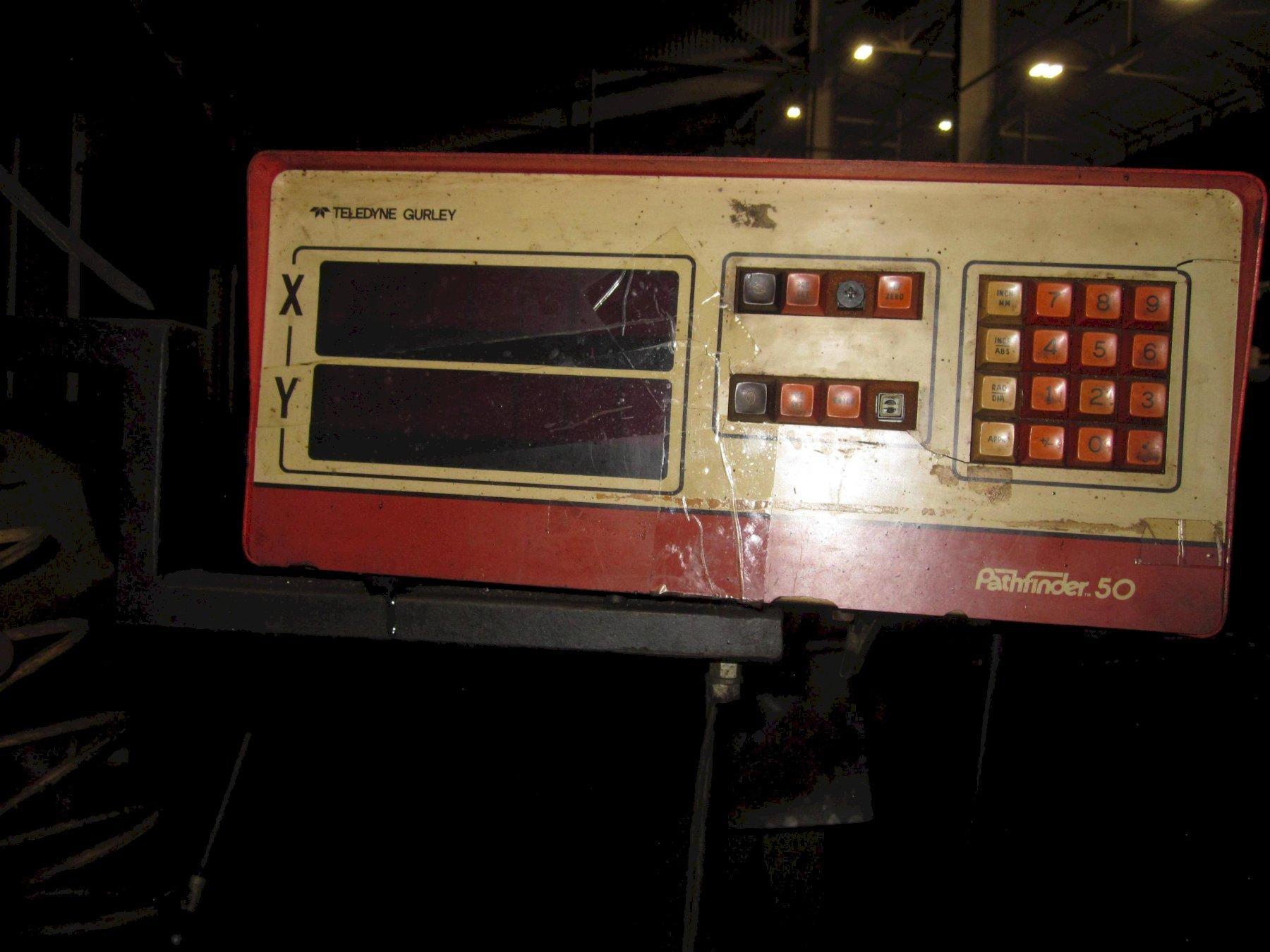

- Precision: With its rigid construction and precise control systems, the Bridgeport milling machine delivers exceptional accuracy. This makes it ideal for producing intricate parts and components with tight tolerances.

- Ease of Use: Despite its advanced capabilities, the Bridgeport milling machine is relatively easy to operate. Its user-friendly controls and intuitive design make it accessible to both experienced machinists and those new to the field.

- Modularity: Bridgeport machines are designed with modularity in mind. This means that various attachments and accessories can be added to expand its functionality, allowing users to customize their setup based on specific project requirements.

- Durability: Built to last, Bridgeport milling machines are renowned for their durability and longevity. The high-quality materials and robust construction ensure that these machines can withstand heavy-duty use and provide reliable performance over an extended period.

Applications and Industries

The Bridgeport milling machine finds applications in numerous industries, showcasing its versatility and adaptability. Here are some key sectors where Bridgeport machines are commonly utilized:

- Aerospace: In the aerospace industry, precision is paramount. Bridgeport milling machines are employed to manufacture critical components such as engine parts, landing gear, and structural elements. Their ability to deliver precise cuts and complex shapes makes them indispensable in this field.

- Automotive: The automotive industry relies on Bridgeport machines for various tasks, including prototyping, production of engine blocks and transmission components, and manufacturing of custom parts. The versatility of Bridgeport milling machines allows automotive manufacturers to streamline their production processes.

- Manufacturing: Bridgeport milling machines are a staple in manufacturing facilities across different sectors. They are used for producing precision parts, tooling, and molds. Their modular design enables manufacturers to adapt to changing production demands and stay competitive in the market.

- Education and Training: Bridgeport milling machines are often used in educational institutions and training centers to teach students the fundamentals of machining. Their user-friendly interface and robust construction make them an excellent choice for introducing aspiring machinists to the world of manufacturing.

Choosing the Right Bridgeport Machine

With a wide range of Bridgeport milling machines available, selecting the right one for your specific needs is crucial. Here are some factors to consider when making your choice:

- Workpiece Size: Evaluate the size and complexity of the workpieces you'll be machining. Different Bridgeport models have varying table sizes and travel capacities, so choose one that accommodates your workpiece dimensions.

- Precision Requirements: Consider the level of precision required for your applications. Bridgeport machines offer various levels of accuracy, so select a model that aligns with your specific precision needs.

- Speed and Power: Evaluate the speed and power requirements of your machining operations. Some Bridgeport machines are designed for high-speed cutting, while others excel in heavy-duty applications. Choose a machine that matches your speed and power expectations.

- Budget: Bridgeport milling machines come in a range of price points. Determine your budget and explore the options available within your price range. It's important to strike a balance between cost and the features and capabilities you require.

Maintenance and Care

To ensure the longevity and optimal performance of your Bridgeport milling machine, proper maintenance and care are essential. Here are some maintenance tips to keep in mind:

- Regular Cleaning: Keep your Bridgeport machine clean and free from chips, debris, and coolant residue. Regular cleaning helps prevent contamination and ensures smooth operation.

- Lubrication: Follow the manufacturer's recommendations for lubricating the machine's moving parts. Proper lubrication reduces friction and wear, extending the lifespan of your Bridgeport milling machine.

- Tool Maintenance: Maintain and sharpen your cutting tools regularly. Dull or damaged tools can affect the quality of your work and increase wear on the machine. Keep a well-organized tool inventory to ensure efficient tool changes.

- Calibration: Periodically calibrate your Bridgeport machine to maintain its accuracy. This involves checking and adjusting the machine's alignment, spindle runout, and other critical parameters.

Tips for Efficient Machining

Maximizing the efficiency of your Bridgeport milling machine can lead to improved productivity and cost-effectiveness. Here are some tips to enhance your machining operations:

- Optimize Cutting Parameters: Experiment with different cutting speeds, feed rates, and depth of cuts to find the optimal combination for your specific material and machining operation. This can help reduce cycle times and improve tool life.

- Utilize Cutting Fluids: Cutting fluids or coolants can significantly enhance the machining process. They help reduce friction, dissipate heat, and improve the surface finish of your workpiece. Choose the appropriate cutting fluid based on your material and machining requirements.

- Tool Selection: Select the right cutting tools for your application. Different materials and machining operations may require specific tool geometries and coatings. Consult with tool manufacturers or machining experts to choose the most suitable tools for your Bridgeport machine.

- Plan Your Setup: Efficiently plan your machining setup to minimize tool changes and reduce non-cutting time. Consider using fixtures, jigs, or clamping systems to securely hold your workpiece and ensure accurate positioning.

Conclusion

The Bridgeport milling machine continues to be a cornerstone in the world of manufacturing and engineering. Its rich history, versatile features, and precision capabilities make it a trusted choice for professionals across various industries. Whether you're a seasoned machinist or a beginner, the Bridgeport milling machine offers a reliable and efficient solution for your machining needs. By understanding its features, applications, and proper maintenance, you can unlock the full potential of this iconic machine and produce high-quality workpieces with precision and accuracy.

What are the common applications of Bridgeport milling machines?

+

Bridgeport milling machines are used in various industries, including aerospace, automotive, manufacturing, and education. They are versatile and can handle a wide range of materials and machining operations.

How do I choose the right Bridgeport machine for my needs?

+

Consider factors such as workpiece size, precision requirements, speed and power needs, and your budget. Evaluate the different Bridgeport models and choose one that aligns with your specific applications and requirements.

What maintenance practices should I follow for my Bridgeport milling machine?

+

Regular cleaning, proper lubrication, tool maintenance, and periodic calibration are essential for maintaining the performance and longevity of your Bridgeport machine. Follow the manufacturer’s guidelines and seek professional advice for optimal maintenance practices.

Can I upgrade or customize my Bridgeport milling machine?

+

Yes, Bridgeport machines are designed with modularity in mind. You can add various attachments, accessories, and upgrades to enhance their functionality and adapt them to your specific needs. Consult with Bridgeport experts or authorized dealers for guidance on customization options.

Where can I find resources and support for my Bridgeport milling machine?

+

Bridgeport Machines, Inc. provides extensive resources, including manuals, technical support, and training materials. Additionally, online forums, user communities, and industry experts can offer valuable insights and assistance. Reach out to authorized dealers or Bridgeport representatives for further support.