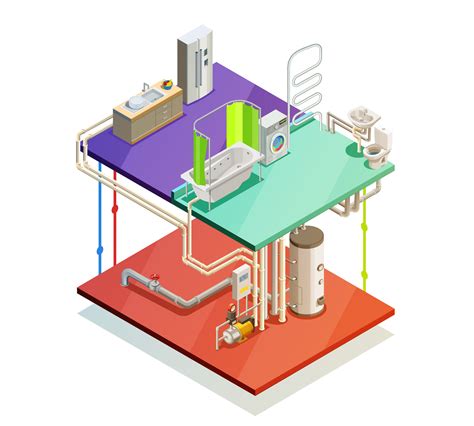

Building an efficient MEP (Mechanical, Electrical, and Plumbing) system is crucial for any construction project. A well-designed MEP system ensures optimal performance, energy efficiency, and comfort for occupants. In this blog post, we will explore seven essential tips to help you design the ultimate MEP system.

1. Conduct a Thorough Site Analysis

Before diving into the design process, it's crucial to conduct a comprehensive site analysis. This step involves evaluating the project's location, climate, and specific requirements. Consider factors such as the building's orientation, prevailing wind direction, and local weather patterns. By understanding the site conditions, you can make informed decisions about the MEP system's design and optimize its performance.

2. Collaborate with Experts

MEP design is a complex task that requires expertise in various fields. Collaborating with professionals, such as mechanical engineers, electrical engineers, and plumbing specialists, is essential. These experts bring their specialized knowledge and experience to the table, ensuring that all aspects of the MEP system are covered. A collaborative approach allows for better coordination, problem-solving, and integration of different systems.

3. Optimize Energy Efficiency

Energy efficiency is a key consideration in modern construction. Designing an energy-efficient MEP system not only reduces operating costs but also minimizes the building's environmental impact. Here are some strategies to achieve optimal energy efficiency:

- Utilize energy-efficient equipment and appliances with high SEER (Seasonal Energy Efficiency Ratio) ratings.

- Implement a building automation system (BAS) to control and monitor energy consumption.

- Consider renewable energy sources like solar panels or wind turbines to supplement the building's energy needs.

- Insulate and seal the building envelope to minimize heat loss or gain.

- Install energy-efficient lighting systems and occupancy sensors to reduce electricity consumption.

4. Plan for Future Expansion

When designing the MEP system, it's important to consider the building's future growth and expansion. Leave room for potential additions or modifications to the mechanical, electrical, and plumbing infrastructure. This proactive approach ensures that the system can accommodate future changes without extensive renovations or disruptions.

5. Implement Redundancy and Backup Systems

To ensure the reliability and continuity of the MEP system, it's crucial to implement redundancy and backup systems. This includes installing backup generators, uninterruptible power supply (UPS) systems, and redundant piping or wiring. By having these backup measures in place, you can minimize the impact of power outages, equipment failures, or other unforeseen events.

6. Prioritize Indoor Air Quality

Indoor air quality (IAQ) is a critical aspect of a healthy and comfortable indoor environment. Poor IAQ can lead to various health issues and discomfort for occupants. To maintain optimal IAQ, consider the following:

- Install high-quality air filters and regularly maintain them to remove pollutants and allergens.

- Implement a balanced ventilation system to ensure adequate fresh air supply and exhaust stale air.

- Utilize air purification systems or UV-C lights to eliminate airborne pathogens.

- Monitor and control humidity levels to prevent mold growth and create a comfortable environment.

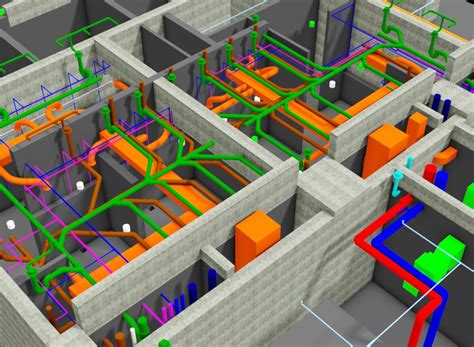

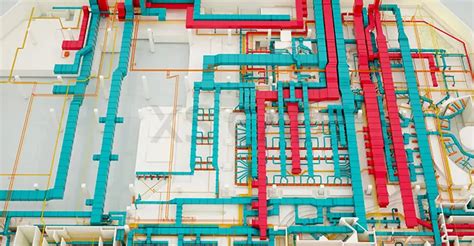

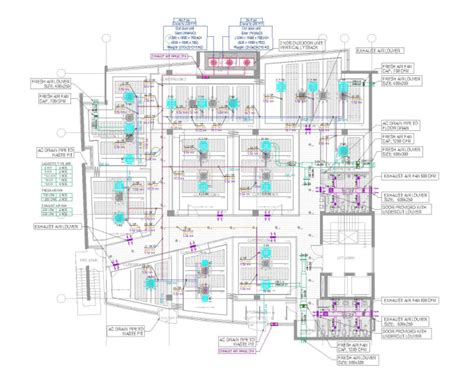

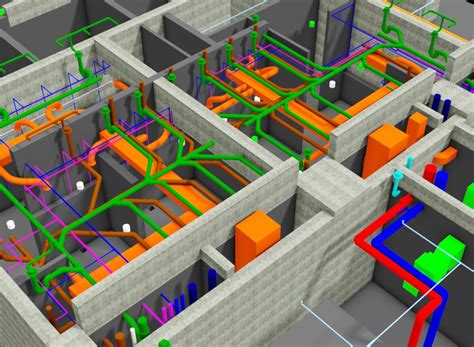

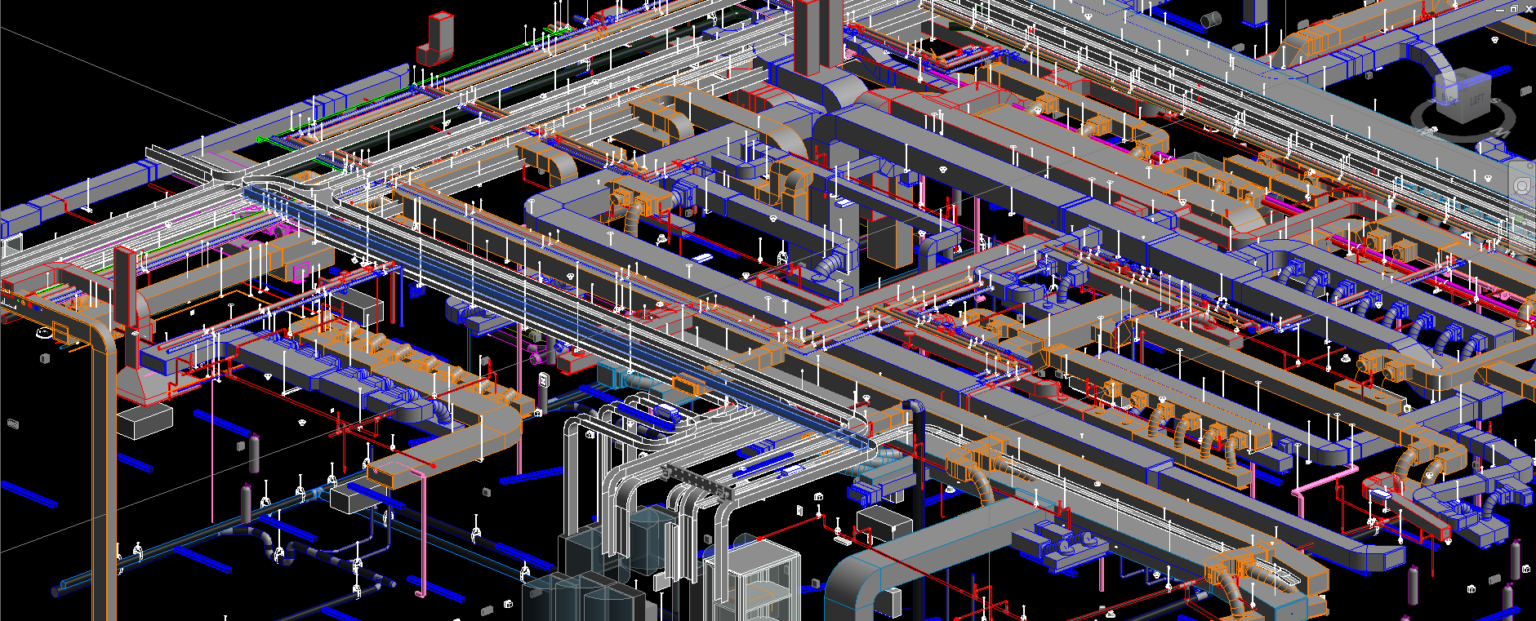

7. Use 3D Modeling and BIM

Leveraging 3D modeling and Building Information Modeling (BIM) can greatly enhance the MEP design process. These tools allow for precise coordination and visualization of the mechanical, electrical, and plumbing systems. By creating a digital representation of the building, you can identify potential clashes, optimize system layouts, and ensure seamless integration with the architectural design.

💡 Note: BIM software, such as Revit, offers powerful features for MEP design, including automated clash detection and coordination.

Conclusionary Notes

Designing the ultimate MEP system requires a holistic approach, considering various factors and collaborating with experts. By conducting a thorough site analysis, optimizing energy efficiency, planning for future expansion, and prioritizing indoor air quality, you can create a well-functioning and sustainable MEP system. Implementing redundancy and utilizing advanced technologies like 3D modeling and BIM further enhance the system's performance and reliability. With these tips in mind, you'll be well on your way to designing an MEP system that meets the highest standards of efficiency and comfort.

Frequently Asked Questions

What is the role of a mechanical engineer in MEP design?

+

Mechanical engineers play a crucial role in MEP design by focusing on the mechanical aspects, such as HVAC (Heating, Ventilation, and Air Conditioning) systems, plumbing, and fire protection. They ensure that these systems are designed efficiently, meet code requirements, and provide optimal comfort for building occupants.

How can I improve the energy efficiency of the MEP system?

+

To enhance energy efficiency, consider using energy-efficient equipment, implementing a building automation system, and incorporating renewable energy sources. Regular maintenance and optimization of the MEP system can also lead to significant energy savings.

What are the benefits of using BIM for MEP design?

+

BIM offers several advantages for MEP design, including improved coordination between different trades, clash detection, and better visualization. It allows for more efficient design, reduces errors, and facilitates better communication and collaboration among the project team.

How can I ensure good indoor air quality in the building?

+

Maintaining good indoor air quality requires a holistic approach. This includes proper ventilation, regular maintenance of air handling units, using high-quality air filters, and controlling humidity levels. Additionally, avoiding the use of harmful materials and implementing air purification systems can further enhance IAQ.

What are some common challenges in MEP design and how can they be addressed?

+

Common challenges in MEP design include space constraints, coordinating with other trades, and meeting energy efficiency goals. To address these challenges, effective communication, early collaboration, and utilizing advanced technologies like BIM can greatly assist in finding efficient solutions.