Molecular polymers are fascinating substances with a wide range of applications, from everyday materials to cutting-edge technologies. Among these polymers, flexible molecular polymers stand out for their unique properties and versatility. In this blog post, we will delve into the world of flexible molecular polymers, exploring their characteristics, synthesis, and diverse uses.

The Intriguing Nature of Flexible Molecular Polymers

Flexible molecular polymers, often referred to as elastomers, possess exceptional elasticity and flexibility. Unlike their rigid counterparts, these polymers can undergo significant deformation and return to their original shape, much like a rubber band. This distinctive property makes them invaluable in various industries, offering a wide range of benefits.

Synthesis and Production

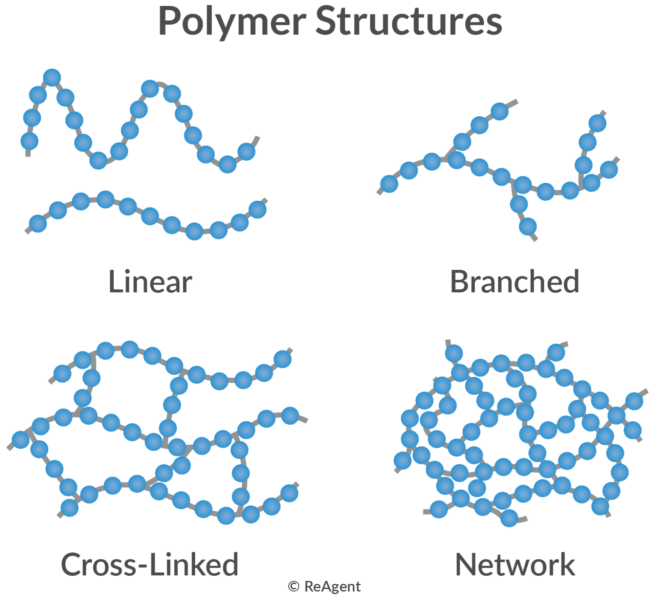

The synthesis of flexible molecular polymers involves intricate chemical processes. Typically, these polymers are derived from monomers through a process called polymerization. Monomers, the building blocks of polymers, are combined in specific ratios and conditions to form long chains or networks. The choice of monomers and the polymerization method play a crucial role in determining the properties of the resulting polymer.

One common method of synthesizing flexible molecular polymers is free-radical polymerization. This process involves the use of initiators, such as peroxides or azo compounds, which generate free radicals. These free radicals then initiate the polymerization reaction, leading to the formation of polymer chains. The length and structure of these chains can be controlled by adjusting the reaction conditions and the ratio of monomers.

Another approach is ionic polymerization, which relies on the use of initiators that generate ions. These ions then propagate the polymerization reaction, resulting in the formation of polymers with well-defined structures. Ionic polymerization often produces polymers with higher molecular weights and better control over the polymerization process.

In addition to these traditional methods, there are also emerging techniques such as controlled/living radical polymerization and ring-opening metathesis polymerization (ROMP). These techniques offer greater precision and control over the polymerization process, allowing for the synthesis of complex polymer architectures and tailored properties.

Key Characteristics and Properties

- Elasticity and Flexibility: The most prominent feature of flexible molecular polymers is their exceptional elasticity. They can stretch and deform significantly without breaking, making them ideal for applications requiring flexibility and resilience.

- Tensile Strength: Despite their flexibility, these polymers exhibit impressive tensile strength. They can withstand significant forces without tearing or rupturing, ensuring their durability and reliability.

- Chemical Resistance: Many flexible molecular polymers demonstrate excellent resistance to various chemicals, including acids, bases, and solvents. This property makes them suitable for use in aggressive environments and chemical-handling applications.

- Thermal Stability: Depending on the specific polymer, they can exhibit good thermal stability, maintaining their properties over a wide temperature range. This characteristic is crucial for applications in extreme conditions.

- Adhesion and Compatibility: Some flexible molecular polymers possess excellent adhesion properties, allowing them to bond strongly with various substrates. This makes them valuable in adhesive and sealant applications.

Applications and Uses

The versatility of flexible molecular polymers is evident in their wide range of applications across multiple industries. Here are some notable uses:

Automotive Industry

- Tire Manufacturing: Flexible molecular polymers, such as synthetic rubbers, are extensively used in tire production. They provide the necessary elasticity and durability, ensuring a smooth and safe driving experience.

- Sealing and Gasketing: These polymers are employed in various sealing applications, including gaskets, O-rings, and seals, to prevent leaks and maintain the integrity of automotive systems.

Medical and Healthcare

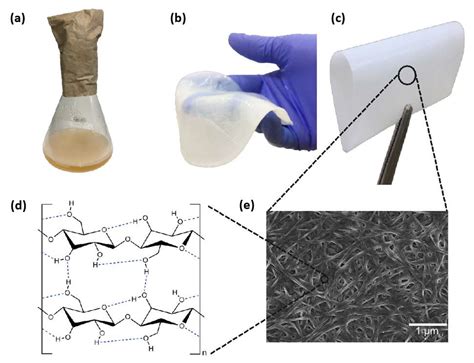

- Medical Devices: Flexible molecular polymers find applications in medical devices like catheters, implants, and prosthetics. Their biocompatibility and flexibility make them suitable for use in the human body.

- Wound Care: Some polymers are used in wound dressings and bandages, providing a flexible and breathable barrier to promote healing.

Construction and Building Materials

- Sealants and Adhesives: Flexible molecular polymers are commonly used as sealants and adhesives in construction. They provide excellent bonding and sealing properties, ensuring the structural integrity of buildings.

- Roofing Materials: Certain polymers, such as ethylene propylene diene monomer (EPDM), are utilized in roofing membranes, offering flexibility and weather resistance.

Consumer Goods

- Sports Equipment: Flexible molecular polymers are integral to the production of sports gear, including footwear, protective gear, and sporting goods. They provide comfort, shock absorption, and durability.

- Toys and Games: Many toys and games feature flexible polymers, offering a safe and playful experience for children.

Electronics and Technology

- Flexible Displays: Some polymers, known as flexible substrates, are used in the production of flexible displays for smartphones, tablets, and wearable devices.

- Conductive Polymers: Certain conductive polymers exhibit flexibility and electrical conductivity, making them suitable for use in flexible electronics and organic light-emitting diodes (OLEDs).

Challenges and Future Prospects

While flexible molecular polymers offer numerous advantages, there are challenges to be addressed. One of the primary concerns is the environmental impact of these polymers, particularly in terms of their production and disposal. Researchers and industries are actively exploring sustainable alternatives and recycling methods to mitigate these concerns.

Furthermore, the development of advanced polymer materials with enhanced properties is an ongoing pursuit. Scientists and engineers are continuously innovating to create polymers with improved mechanical, thermal, and electrical characteristics, expanding their applications even further.

Conclusion

Flexible molecular polymers, with their remarkable elasticity and versatility, have become indispensable in various industries. From automotive to healthcare, construction to electronics, these polymers play a crucial role in enhancing the performance and functionality of countless products. As research and development continue to advance, we can expect even more innovative uses and improvements in the field of flexible molecular polymers.

What are some common examples of flexible molecular polymers?

+

Some common examples include natural rubber, synthetic rubbers like butadiene rubber and silicone rubber, as well as thermoplastic elastomers such as styrene-butadiene-styrene (SBS) and thermoplastic polyurethane (TPU).

How do flexible molecular polymers differ from rigid polymers?

+

Flexible molecular polymers, or elastomers, possess unique properties such as high elasticity and flexibility, allowing them to deform and recover their shape. In contrast, rigid polymers, like polyethylene or polypropylene, are more rigid and lack the same level of elasticity.

Are there any environmental concerns associated with flexible molecular polymers?

+

Yes, the production and disposal of flexible molecular polymers can have environmental impacts. However, sustainable alternatives and recycling methods are being explored to address these concerns and promote a more eco-friendly approach.

What are the key advantages of using flexible molecular polymers in the automotive industry?

+

Flexible molecular polymers offer excellent durability, flexibility, and resistance to various environmental factors, making them ideal for use in tires, seals, and other automotive components. They provide enhanced performance, safety, and comfort for vehicles.